61.1K

Downloads

311

Episodes

Join Renaud Anjoran, Founder & CEO of Sofeast, in this podcast aimed at importers who develop their own products as he discusses the hottest topics and shares actionable tips for manufacturing in China & Asia today!

WHO IS RENAUD?

Renaud is a French ISO 9001 & 14001 certified lead auditor, ASQ certified Quality Engineer and Quality Manager who has been working in the Chinese manufacturing industry since 2005. He is the founder of the Sofeast group that has over 200 staff globally and offers services (QA, product development & engineering, project management, Supply Chain Management, product compliance, reliability testing), contract manufacturing, and 3PL fulfillment for importers and businesses who develop their own products and buyers from China & SE Asia.

WHY LISTEN?

We‘ll discuss interesting topics for anyone who develops and sources their products from Asian suppliers and will share Renaud‘s decades of manufacturing experience, as well as inviting guests from the industry to get a different viewpoint. Our goal is to help you get better results and end up with suppliers and products that exceed your expectations!

Episodes

Friday Jun 17, 2022

An Effective QA Program For New Electronic Products

Friday Jun 17, 2022

Friday Jun 17, 2022

In this episode...

Our CEO Renaud and Adrian from the Sofeast team delve into what a great Quality Assurance program for new electronic products looks like, as new products come with a large number of unknown risks (there are many things that can go wrong in terms of components, firmware, testing, production processes, and more, which we'll get into).

Controlling these risks has become harder for importers since Covid as it's not always possible to travel to China (and other Asian countries to a lesser extent) easily or at all, meaning that they were not able to oversee the development and manufacturing of their products increasing the risks of them going into production with problems.

So, how to use local resources to do Quality Assurance activities to control those risks in your new electronic product, and what does a QA program for new electronics include?

Show Sections

00:00 - Greetings, mentioning Renaud's recent trip to India to check out component suppliers.

01:55 - Introducing the topic: Why Quality Assurance is particularly important for new electronics that have a lot of risks.

Electronics QA Program

07:21 - Activities to do at the start of product development.

20:34 - Activities do when the design is frozen and we're transferring to manufacturing.

27:49 - Activities to do during mass production.

31:08 - Wrapping up.

Related content...

- Sofeast provides electronics QA programs for our clients - explore them & get a quotation for your project!

- Watch as Renaud walks you through a typical QA program in this video

- Read The New Product Introduction Process Guide for Hardware Startups

- Watch New Product Introduction Process Walkthrough (For New Electronic Products)

- Read What Is A Quality Assurance Plan?

- Listen to The NPI Process: Trouble Awaits If You Skip Its Steps!

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

- Apple Podcasts

- Spotify

- Stitcher

- Google Podcasts

- TuneIn

- Amazon Podcasts

- Deezer

- iHeartRADIO

- PlayerFM

- Listen Notes

- Podcast Addict

- Podchaser

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Monday Jun 13, 2022

BONUS: Renaud Tours India, June ’22. Is it a good China-alternative?

Monday Jun 13, 2022

Monday Jun 13, 2022

In this episode...

Renaud comes to you live from Chennai where he's been travelling around India for two weeks exploring a lot of different types of component suppliers. He reports back on what he's learnt on this visit, how India has been changing, and why there seem to be many reasons now to consider India as an alternative to China for, at least, some of your production.

Renaud covers:

- Which areas he visited & regional differences

- Political stability

- What types of suppliers could be alternatives to Chinese counterparts

- Manual Work VS Automation

- Where China still trumps India, for now

- Who has already been moving to India

- Benefits he found about dealing with factory owners and managers, and their operations, over those in China

- Is India still let down by a lack of component suppliers for your supply chain?

Sofeast does a lot of work in India, and some of our clients are asking about moving sourcing and production out of China to more stable countries. If you're thinking the same, this quick bonus episode will be very educational!

Related content...

- Read our blog posts about sourcing from India

- Pros and cons of sourcing products in India vs. China

- Manufacture in China, Vietnam, India, or Elsewhere? [Podcast]

- Our local team in India can provide new supplier identification to help you source great components and manufacturers there

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

- Apple Podcasts

- Spotify

- Stitcher

- Google Podcasts

- TuneIn

- Amazon Podcasts

- Deezer

- iHeartRADIO

- PlayerFM

- Listen Notes

- Podcast Addict

- Podchaser

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday Jun 03, 2022

Increasing Visibility Over Your Supply Chain

Friday Jun 03, 2022

Friday Jun 03, 2022

In this episode...

A common problem that buyers from China particularly suffer from is a lack of transparency and control over their supply chains.

Do you know exactly who supplies your main supplier at all times? If the answer is no, this episode is for you, especially if you are worried about compliance, safety, quality, reliability, and the reputation of your business.

Sofeast CEO Renaud and Adrian from the team go over the risks of lacking visibility over your supply chain, why it's becoming even more important, and some best practices that will help you have more transparency and control.

Show Sections

00:00 - Greetings & Introduction to today's topic: how to increase visibility over your supply chain

03:05 - Does everyone know who's in their supply chain?

05:18 - Background: Regulations coming into action requiring more supply-chain visibility.

11:29 - Real examples of people we've worked with at Sofeast who suffered problems caused by a lack of visibility over their supply chains.

14:06 - Do Chinese suppliers often try to hide supply chain info and why?

19:18 - The drawbacks of NOT having visibility over your supply chain.

- You will suffer from more unwelcome surprises because if you don't have visibility, you don't have control.

- You are at risk of very bad PR.

- Product quality issues are probably going to more common.

- Production will be more inefficient.

31:19 - Best practices that will help you have better supply chain visibility.

- Tips if you're developing your own products

- Tips if you're buying products off-the-shelf

- Confirm that you're buying from a manufacturer rather than a trading company

- Have a manufacturing agreement

38:18 - Wrapping up.

Related content...

- Get help to source suppliers and products from Sofeast

- 8 Elements of a Low-Risk Supply Chain in China [Webinar]

- How To Push a Chinese or Vietnamese Supplier for Supply Chain Transparency

- How To Qualify A Contract Manufacturer Or Component Supplier [Podcast]

- Developing New Products? Which Suppliers Are The Right Fit For You?

- Have You Revised your Supply Chain Risk Analysis?

- 6 Steps and 1 Key To Reduce Subcontracting Risks in China

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

- Apple Podcasts

- Spotify

- Stitcher

- Google Podcasts

- TuneIn

- Amazon Podcasts

- Deezer

- iHeartRADIO

- PlayerFM

- Listen Notes

- Podcast Addict

- Podchaser

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday May 27, 2022

6 Tips to Improve your Supplier’s Quality - Sourcing from China (Part 8)

Friday May 27, 2022

Friday May 27, 2022

In this episode...

We’re diving back into our series of episodes on how to do your own sourcing from China, from finding suppliers, getting the products manufactured, and through to post-cooperation soft skills such as building rapport with them, following up on production, and today’s topic: Improving the product quality that you’re getting from your now current supplier with 6 tips and best practices from Sofeast's CEO Renaud Anjoran.

Who doesn't want better product quality from existing manufacturers, right?

By the way, this is part 8 of this series, and if you want to go back and listen to every earlier part of this series check out the links below.

Show Sections

00:00 - Greetings & Introduction

02:29 - Are product defects impossible to avoid?

Some advice for getting towards zero defects (with low/no capital investment)

07:53 - The supplier needs to be incentivised to care about quality

10:54 - Tip 1: Beware of batch and queue

15:57 - Tip 2: Local management needs to build up a disciplined culture

21:06 - Tip 3: Getting operators to do some QC work

26:23 - Tip 4: Implement a usability engineering approach & mistake-proofing

31:35 - Tip 5: Clear work instructions & staff training

37:18 - Tip 6: Process controls

41:54 - Wrapping up.

Related content...

- Part 1: Good Fit, Sourcing, Vetting, & Backups [Podcast]

- Part 2: Negotiations, Terms, Leverage, & Quality Standards [Podcast]

- Part 3: Project Management & Checking Quality Early [Podcast]

- Part 4: Final Inspections [Podcast]

- Part 5: Building Rapport [Podcast]

- Part 6: Hands-on or hands-off buyer? [Podcast]

- Part 7: How To Develop Your Chinese Supplier? [Podcast]

- Quality Assurance In China Or Vietnam For Beginners [eBook] 👈 Download for free

- Many more blog posts about quality

- The Sofeast group's own contract manufacturing subsidiary: Agilian Technology

These resources will also help you understand how to build relationships with suppliers or improve (or end) those that you already have:

- Get help to find a good manufacturer in China with this free eBook

- When a relationship turns sour with a Chinese supplier

And, if all else fails and you need to ditch your current supplier and switch to a new one...

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

- Apple Podcasts

- Spotify

- Stitcher

- Google Podcasts

- TuneIn

- Amazon Podcasts

- Deezer

- iHeartRADIO

- PlayerFM

- Listen Notes

- Podcast Addict

- Podchaser

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday May 20, 2022

How To Develop New Apparel (Feat. Belinda Jacobs from Techpacks.co)

Friday May 20, 2022

Friday May 20, 2022

In this episode...

Our CEO Renaud is joined by another special guest, Belinda Jacobs founder of Techpacks.co, a company that has been helping soft goods designers and brands improve production & decrease waste, through tech packs since 2016.

On the podcast we have often discussed electrical and mechanical products, but how do you develop and bring new apparel to the market? Who better to help Renaud explain than Belinda who's an expert in the field! Together they explain what tech packs are and go through the apparel development and production process step by step pointing out best practices and potential pitfalls along the way.

Show Sections

00:00 - Greetings & Introduction to today's topic.

01:07 - Belinda's background and business, Techpacks.co

02:58 - What are tech packs?

05:51 - Do apparel manufacturers have the tendency to skip a lot of pre-production steps and rush straight into mass production unless they're told very clearly what actions to take beforehand by the customer?

The apparel development steps one by one

08:42 - Initial design.

09:53 - Why using another brand's garment as a basis for yours is dangerous.

12:52 - What comes first? Sizing, or an initial sample from the supplier for you to check the look of the garment?

14:18 - After your preliminary plan, the importer asks the manufacturer to prepare some elements. What are they?

17:18 - How do designers communicate their ideas for colors to the manufacturer, and what do they give you for approval?

20:08 - The manufacturer has produced a sample in the right style, color, and fit, what's the next step?

21:44 - Full size set samples. Needed, or not?

24:02 - When do labelling and packing need to be documented and confirmed?

27:26 - What's the best way to communicate with suppliers once you start working with them?

29:34 - At what point will importers feel confident to pay the downpayment and start mass production?

33:07 - What are 'TOP samples?'

36:01 - Summary: The garment development process that designers need to keep in mind

39:53 - Wrapping up and how to contact Belinda and Techpacks.co

Related content...

- What does CMT (Cut, Make & Trim) mean?

- Some Problems Can’t Be Detected During Apparel QC Inspections

- Auditing Cut & Sew Processes for Garment Manufacturing

- How The Gap Increases Speed in their Apparel Supply Chain

- 3 Basic Guidelines for Garment Quality Assurance in China

- Implement a Production Monitoring Program for Apparel in China, India, & Vietnam from Sofeast where our experts handle the development and production steps described in this episode locally.

- Get help from Sofeast to assure your apparel production starts with lower risks with a Pre-Production Meeting.

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

- Apple Podcasts

- Spotify

- Stitcher

- Google Podcasts

- TuneIn

- Amazon Podcasts

- Deezer

- iHeartRADIO

- PlayerFM

- Listen Notes

- Podcast Addict

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday May 13, 2022

Friday May 13, 2022

In this episode...

Our CEO Renaud is joined by a special guest in this episode, Andrew Hupert, a cross-cultural management and communication expert, coach, and trainer who spent 10+ years in China, is currently based in Mexico, and also creates a podcast you should check out: Globalism 2.0.

They discuss why companies are starting to leave China, in particular, American companies, where they're going, and why Western companies need to start thinking about diversifying supply chains rather than focusing on China alone. Andrew also gives some helpful insight into the business environment of Mexico and why it is a candidate for near-shoring supply chains for some American and Canadian companies.

Show Sections

00:00 - Greetings & Introduction to today's topic.

03:04 - Andrew's background.

04:21 - What is 'Globalism 2.0?'

13:29 - What is a bad scenario in the next few years that companies who manufacture products in China for sale in the USA need to plan for?

21:59 - Is there a timetable where the situation between China and the US becomes very hard for importers?

22:57 - Implementing China +1 and going further.

26:27 - Is Vietnam a potential China alternative?

29:56 - Have a lot of companies selling into the USA & Canada already near-shored their supply chains into Mexico?

33:15 - What's the relationship between Mexico and China?

40:22 - Wrapping up.

Related content...

- Read Andrew's book: The Fragile Bridge: Conflict Management in Chinese Business

- Follow Andrew on LinkedIn to read his latest posts

- Listen to Andrew's podcast, Globalism 2.0

- Why Your Product’s Final Assembly Should Be Close To Its Key Components

- When Should American Companies Reshore Manufacturing Or Stay In China?

- How To Diversify Manufacturing Sources Out of China and Cut Risk

- Nearshoring To Mexico. An Alternative To China? [Podcast]

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

- Apple Podcasts

- Spotify

- Stitcher

- Google Podcasts

- TuneIn

- Amazon Podcasts

- Deezer

- iHeartRADIO

- PlayerFM

- Listen Notes

- Podcast Addict

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday May 06, 2022

Friday May 06, 2022

In this episode...

Renaud answers 3 great questions that came in from our listeners, assisted by Adrian from the Sofeast team.

He'll cover how to communicate fabric quality to suppliers, tactics for coping with US tariffs on China-made goods, and strategies to cope with volatile material costs today.

Show Sections

00:00 - Greetings & Introduction

01:43 - "How to communicate the quality of materials/fabrics you want to buy to your supplier..? There are qualitative aspects that are outside a fabric spec description."

13:02 - How to minimize tariffs on China-made goods imported to the USA under our brand?

24:58 - Any tactics for handling volatile material and shipping costs today?

32:03 - Is China as affected by energy cost rises as other regions right now?

34:32 - Wrapping up.

Related content...

- Plastic, Silicone, Steel, and Others: Updated China Raw Materials Costs (Late Feb ’22)

- Rising Raw Material Prices: What Strategy To Follow? (6 Approaches)

- How To Cooperate With Your Chinese Supplier, Part 16: Bad News from China, Raw Material Prices Just Increased!

- How To Switch To A Newer, Better Chinese Manufacturer? [eBook]

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

- Apple Podcasts

- Spotify

- Stitcher

- Google Podcasts

- TuneIn

- Amazon Podcasts

- Deezer

- iHeartRADIO

- PlayerFM

- Listen Notes

- Podcast Addict

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday Apr 29, 2022

Levels of Quality Standards (from Basic to Advanced)

Friday Apr 29, 2022

Friday Apr 29, 2022

In this episode...

In order for your manufacturer to truly understand what you expect from them a quality standard for your product is required. This lays out how the product should look, its components and materials, what defects are and aren't acceptable (if any), its color, and so many other important aspects that Renaud will go into here.

There are different levels of quality standards, from most basic to advanced...you'll see how they all fit together to keep everyone aligned and reduce quality problems from the start of your cooperation with the supplier.

Show Sections

00:00 - Greetings & Introduction

01:03 - What are quality standards?

07:51 - Does every importer implement a clear standard?

10:41 - 1. The golden sample.

16:20 - 2. Specifications sheet.

27:13 - 3. Defect board.

29:23 - 4. Boundary samples.

34:37 - How to handle and keep physical samples safe?

38:19 - Avoiding different conclusions being drawn during inspections by confirming the measurement system to be used, etc.

41:57 - Wrapping up.

Related content...

- Product specifications template for importers in China [FREE download]

- Documenting Your Company’s Quality Standard into the Details

- Is your China factory’s quality standard too low?

- Golden Sample: Why You Need It Before Mass Production Starts

- Why Is A Pre-Production Sample So Important? [Podcast]

- Quality Control Plan: Defining Expectations Before Production

- Product quality inspections in China/Asia [solutions from Sofeast]

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

- Apple Podcasts

- Spotify

- Stitcher

- Google Podcasts

- TuneIn

- Amazon Podcasts

- Deezer

- iHeartRADIO

- PlayerFM

- Listen Notes

- Podcast Addict

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday Apr 22, 2022

What Happens If You Decide To Leave Your Chinese Supplier?

Friday Apr 22, 2022

Friday Apr 22, 2022

In this episode...

A few episodes ago we put a call out to listeners for questions about manufacturing, especially in China, that they'd like Sofeast's CEO Renaud Anjoran to answer.

One particularly good question that would require too long an answer for just one section of an episode was:

What checklist of activities does an importer need to perform when ending business relationships with a Chinese contract manufacturer?

So, in this episode, Renaud takes you through what happens if you decide to leave your Chinese supplier, including reasons why you'd need to, how to manage the process, and some of the typical actions that need to be taken (in a kind of checklist).

Show Sections

00:00 - Greetings & Introduction

01:47 - Why can starting the process to leave your Chinese supplier be tricky?

06:29 - Reasons why you might decide to leave a supplier.

19:49 - Why the difficulty of doing business with Chinese suppliers these days may force some businesses to move away from even good suppliers.

21:26 - How to manage the process of moving production out of one factory in China to another?

27:31 - How to onboard your new manufacturer?

30:09 - What to do about your tooling?

36:21 - Lying to a supplier to ease a move. Yes, or no?

38:39 - What activities should we plan to do when transferring production from one supplier to a new one?

40:57 - Wrapping up.

Related content...

- 7 Reasons To Switch To A New Chinese Manufacturer

- Tips to Manage the Transfer of Production To Another Chinese Factory

- How To Plan for Transferring Production To a New Factory: 45 Point Checklist

- Get help to find a good manufacturer in China with this free eBook

- When a relationship turns sour with a Chinese supplier

- How To Switch To A Newer, Better Chinese Manufacturer? [eBook]

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

- Apple Podcasts

- Spotify

- Stitcher

- Google Podcasts

- TuneIn

- Amazon Podcasts

- Deezer

- iHeartRADIO

- PlayerFM

- Listen Notes

- Podcast Addict

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday Apr 15, 2022

How to develop your Chinese suppliers? - Sourcing from China (Part 7)

Friday Apr 15, 2022

Friday Apr 15, 2022

In this episode...

Many importers are new to sourcing from China so we've been creating a mini-series of episodes that explores the sourcing process with advice and best practices from Sofeast's CEO Renaud Anjoran.

In this series of episodes, we’re exploring how to do your own sourcing from China, from finding suppliers for your products to getting them made.

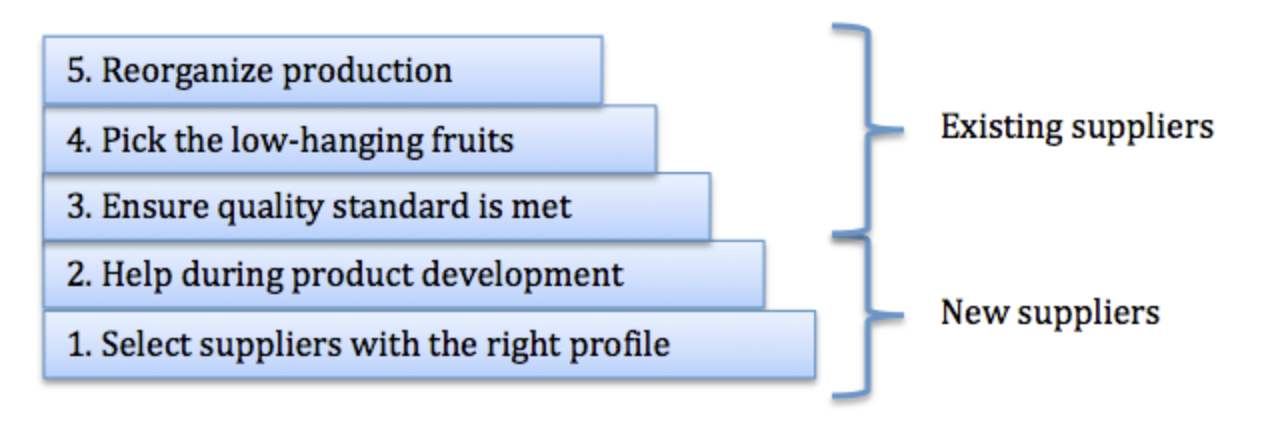

Last time in episode 98 we discussed how to follow up on ongoing production and what it means to be a hands-on or hands-off buyer, and continuing on with soft skills like this we’re now at the point where we’re working with a supplier who’s doing our manufacturing for us in China (or elsewhere in Asia), and the question is: how to develop them for better performance and results, and what sort of results should we be aiming for? This is where implementing a development program comes into it!

Show Sections

00:00 - Greetings & Introduction

02:20 - What is supplier development and is it overlooked by buyers?

Next, we'll go into what a supplier development program includes:

08:36 - 1. Selecting suppliers with the right profile.

12:43 - 2. Helping the supplier during product development and new productions.

17:09 - How phases 1 & 2 are connected to being a hands-on buyer and building rapport with the supplier.

18:44 - 3. Ensure your quality standard is met.

27:34 - Proactive approaches. 4. Targeting low-hanging fruits (small projects for quick wins).

33:05 - 5. Reorganizing manufacturing and/or supply chain processes.

38:51 - Summarizing what a supplier development plan is.

40:46 - When is supplier development worthwhile over switching suppliers and starting again?

41:45 - Why we started our own contract manufacturing subsidiary to embody the best practices discussed here.

43:21 - Wrapping up.

Related content...

- Part 1: Good Fit, Sourcing, Vetting, & Backups [Podcast]

- Part 2: Negotiations, Terms, Leverage, & Quality Standards [Podcast]

- Part 3: Project Management & Checking Quality Early [Podcast]

- Part 4: Final Inspections [Podcast]

- Part 5: Building Rapport [Podcast]

- Part 6: Hands-on or hands-off buyer? [Podcast]

- Developing a Chinese Supplier

- The Sofeast group's own contract manufacturing subsidiary: Agilian Technology

These resources will also help you understand how to build relationships with suppliers or improve (or end) those that you already have:

- Get help to find a good manufacturer in China with this free eBook

- When a relationship turns sour with a Chinese supplier

And, if all else fails and you need to ditch your current supplier and switch to a new one...

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

- Apple Podcasts

- Spotify

- Stitcher

- Google Podcasts

- TuneIn

- Amazon Podcasts

- Deezer

- iHeartRADIO

- PlayerFM

- Listen Notes

- Podcast Addict

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB