61.8K

Downloads

315

Episodes

Join Renaud Anjoran, Founder & CEO of Sofeast, in this podcast aimed at importers who develop their own products as he discusses the hottest topics and shares actionable tips for manufacturing in China & Asia today!

WHO IS RENAUD?

Renaud is a French ISO 9001 & 14001 certified lead auditor, ASQ certified Quality Engineer and Quality Manager who has been working in the Chinese manufacturing industry since 2005. He is the founder of the Sofeast group that has over 200 staff globally and offers services (QA, product development & engineering, project management, Supply Chain Management, product compliance, reliability testing), contract manufacturing, and 3PL fulfillment for importers and businesses who develop their own products and buyers from China & SE Asia.

WHY LISTEN?

We‘ll discuss interesting topics for anyone who develops and sources their products from Asian suppliers and will share Renaud‘s decades of manufacturing experience, as well as inviting guests from the industry to get a different viewpoint. Our goal is to help you get better results and end up with suppliers and products that exceed your expectations!

Join Renaud Anjoran, Founder & CEO of Sofeast, in this podcast aimed at importers who develop their own products as he discusses the hottest topics and shares actionable tips for manufacturing in China & Asia today!

WHO IS RENAUD?

Renaud is a French ISO 9001 & 14001 certified lead auditor, ASQ certified Quality Engineer and Quality Manager who has been working in the Chinese manufacturing industry since 2005. He is the founder of the Sofeast group that has over 200 staff globally and offers services (QA, product development & engineering, project management, Supply Chain Management, product compliance, reliability testing), contract manufacturing, and 3PL fulfillment for importers and businesses who develop their own products and buyers from China & SE Asia.

WHY LISTEN?

We‘ll discuss interesting topics for anyone who develops and sources their products from Asian suppliers and will share Renaud‘s decades of manufacturing experience, as well as inviting guests from the industry to get a different viewpoint. Our goal is to help you get better results and end up with suppliers and products that exceed your expectations!

Episodes

Friday Mar 01, 2024

Plastic & Metal Development Prototypes: Uses & Limitations

Friday Mar 01, 2024

Friday Mar 01, 2024

Adrian hosts and is joined by Sofeast Group senior engineer, Paul Adams, and they talk about the uses and limitations of the metal and plastic 'development prototypes,' that is to say, product prototypes made during the development process and before mass production. Remember, these are not production-standard prototypes, but that doesn't mean that they aren't important as you will find out...it's all about controlling expectations.

Show Sections

00:00 - Greetings and introduction

02:06 - Why are we producing prototypes to start with?

04:09 - Plastic prototyping processes.

07:02 - 3D-Printed plastic development prototype limitations.

12:10 - The trade-off between quality and cost when it comes to prototypes.

15:34 - Metal prototyping processes.

18:18 - Metal development prototype limitations.

22:48 - Key limitations of development prototypes.

29:35 - Considerations for you regarding prototypes.

32:56 - Wrapping up.

Related content...

- Rapid Tooling Prototyping Guide

- Plastic Enclosures for Electronics Projects (Plastics Sourcing Guide)

- CNC Prototyping In Metal And Plastic

- Development Prototypes for Parts: Issues and Limitations (2 examples)

- Mold Tech Texture Book

- Get help from Sofeast's engineering team to develop your prototoypes

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday Feb 23, 2024

Handing Over To Manufacturing: Best Practices

Friday Feb 23, 2024

Friday Feb 23, 2024

Adrian and Renaud discuss how to plan for the handover of your innovative new product to manufacturing (with a focus on hard goods with mechanical elements and some electronic/electrical parts). Product handover should be a structured process of actions taken mainly before the manufacturer gets involved to ensure a smooth transition from you to them so the product ends up being made to your specifications and requirements and the risks of issues before product launch are minimized.

You'll learn:

- What a product handover is.

- The drawbacks of not following a structured process and how not to hand over.

- What the best practices for handover are so you can follow them to streamline your next project.

Show Sections

00:00 - Greetings and introduction

00:50 - Who needs to hand over their product to a manufacturer and why?

04:22 - The WRONG way to hand over to the manufacturer.

09:57 - Questions about the product that need to be answered.

12:55 - Who will do the DFM?

15:32 - What can happen if you just throw designs over the wall to a manufacturer without doing a DFM review?

18:15 - Handover best practices.

35:14 - When is the handover complete?

37:59 - Wrapping up.

Related content...

- Avoid Sending Immature Product Designs to a Chinese Manufacturer! [Podcast]

- Sourcing Chinese Manufacturers: Western Or Chinese Model? [Podcast]

- DIY Sourcing From China Part 1: Good Fit, Sourcing, Vetting, & Backups [Podcast]

- OEM, ODM, Contract Manufacturers: Which Chinese Supplier To Choose?

- The Danger of Developing your Custom Product with an ODM Factory

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday Feb 16, 2024

Friday Feb 16, 2024

Renaud hosts today and welcomes guest speaker Amit Rosenthal, CEO of Proboxx, to the show and this episode's focus is on moving your products from Asia to where they need to be via freight forwarding. They discuss how the latest technological advancements in freight forwarding are streamlining operations, improving tracking and transparency, and offering more reliable and efficient services for Amazon sellers.

Since many people manufacturing overseas end up selling on Amazon, at least as part of their mix, being up to speed on moving your products is useful, so hit that play button!

Show Sections

00:00 - Greetings and introduction of Amit and his freight forwarding business, Proboxx.

06:03 - How and why freight forwarding needed to go from old-fashioned to cutting edge.

13:20 - Why not knowing their shipment's arrival date at the distribution facility can make life difficult for sellers.

19:21 - How do Amazon sellers plan their sales?

22:31 - Are GPS trackers for the products in a container helpful?

26:33 - Many small freight forwarders set up in China since around 2020 are going bust, how does this affect overseas customers?

32:05 - Wrapping up.

Related content...

- Learn more about Proboxx and how they can help you

- Impact of Yemen’s Houthis On Global Shipping in Jan ’24 [Bonus Podcast]

- Types of Incoterms (Guides)

- How Does International Shipping Work?

- FOB Risk Of Loss Is A Real Problem. Don’t Be Caught Out!

- HS vs HTS Codes: How to Find the Right Code for your Product? (incl. Links to Official Sources)

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday Feb 09, 2024

What's A Good QA Auditing & Inspection Program For New Products?

Friday Feb 09, 2024

Friday Feb 09, 2024

Adrian and Renaud go through what makes a good QA auditing and inspection program for innovative new electro-mechanical products that will reduce risks of poor quality, reliability, and compliance, and detect the issues in time for them to be worked on before anything is shipped. Unless you are producing simple products or working with a supplier who is very experienced in manufacturing the exact product type you're developing, you will very likely require some form of QA program like this.

It's split into 5 points: 1-3 cover the preparation of the product and process design, then 4-5 are after the product starts mass production. Listen and explore what needs to happen to power up your product quality!

Show Sections

00:00 - Greetings and introduction

01:37 - Why do you need a QA auditing and inspection program?

06:53 - #1. A DFM review of some components (especially custom-designed).

10:50 - #2. A quality system audit of suppliers’ factories.

18:00 - Are market surveillance authorities scrutinising product compliance more than before?

21:13 - #3. Production line preparation audit at the assembly factory.

28:46 - #4. A product inspection during the pilot run(s).

33:12 - #5. Final product inspections during and after production.

41:09 - Wrapping up.

Related content...

- Explore Sofeast factory audits and product inspections

- Documenting Your Company’s Quality Standard into the Details

- What Is A Quality Assurance Plan?

- Product Quality Checklist: How To Prepare It

- How To Choose Which Factory Audit You Need?

- How To Choose Which Product Quality inspection You Need?

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday Feb 02, 2024

Why NOT doing ESD testing on new electronic products is scary!

Friday Feb 02, 2024

Friday Feb 02, 2024

On this episode of the China Manufacturing Decoded Podcast, Adrian hosts and is joined by Andrew, our reliability and compliance expert, from the Sofeast Group for a deep dive into electrostatic discharge (ESD) – a critical factor in electronics production with the potential for significant impact on product success and customer satisfaction. They stress the importance of ESD testing for bulk-manufactured electronics and discuss the potential consequences of failing to consider ESD in manufacturing, such as financial loss and product recalls.

Beyond providing an overview of ESD's significance, this conversation also introduces listeners to three methodologies used for its testing: The Human Body Model (HBM), the Machine Model (MM), and the Charged Device Model (CDM). Andrew elucidates these models, their unique benefits, and their most appropriate application industries as part of a comprehensive ESD discussion.

The need for ESD-resistant design, sound manufacturing environments, and ESD-protective packaging are a few of the critical preventative measures emphasized. Additionally, the roles of regular auditing and assessments for maintaining compliance and enhancing manufacturing methods are also underscored. The episode culminates with specific ESD requirements and testing protocols per product, concluding with insights on how a comprehensive ESD prevention approach can help avoid product returns and financial disparities.

This episode equips listeners with the knowledge needed for safeguarding their electronic products against ESD, enlightening them about its potential damage, and details preventive measures for ESD in the manufacturing process.

Show Sections

00:00 - Greetings and introduction.

02:24 - What is ESD?

06:59 - 3 ESD test models.

13:41 - Common tests and voltages.

18:53 - The harm or damage that can be caused by ESD.

25:42 - How to prevent the effects of ESD?

35:53 - Product design to prevent ESD.

38:34 - Wrapping up.

Related content...

- ESD definition

- What To Do If You Have A High Product Return Rate? [6-step Process]

- Get help and advice from our testing lab if you have questions about ESD testing

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Monday Jan 29, 2024

Impact of Yemen's Houthis On Global Shipping in Jan '24 (BONUS)

Monday Jan 29, 2024

Monday Jan 29, 2024

Welcome to our special 200th episode of China Manufacturing Decoded, a podcast by Sofeast Group, where we discuss global manufacturing topics to help you decode and navigate the supply chain world.

In this episode, we discuss the impact of the Houthi Yemeni rebels' attacks on shipping in the Red Sea, and how it may affect your shipping costs and other issues you might face. We're joined by our very own Kate Oliynykova, Head of Supply Chain Management at Sofeast Group, who shares her insights on the current political events and their potential ripple effects on importers. Listen in as we unravel the complexity of this issue.

The Red Sea route accounts for 12% of global trade, including 30% of the container traffic passing through the Suez Canal. Any disruption in this route affects not only oil and gas prices but also the availability and cost of a broad range of goods. The current attacks have caused a direct increase in ship insurance costs, prompting bigger shipping companies to opt for alternative routes around the Cape of Good Hope. This, in turn, not only escalates transportation costs but also significantly extends delivery times.

In this scenario, we advise importers to diversify their supply chain, considering options like rail or truck deliveries, or partial shipments with air freight.

What are the repercussions if the situation is prolonged? How can importers better prepare for these unforeseen circumstances? Tune in to this episode of China Manufacturing Decoded as we discuss the critical aspects of this multinational issue. Remember, the Sofeast Group offers an in-house logistics department to help formulate a tailored solution that meets your needs most cost-effectively, given the present situation.

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday Jan 26, 2024

Friday Jan 26, 2024

In this insightful episode, host Renaud Anjoran and senior engineer Paul Adams delve into the intriguing world of the 'experience effect' - a phenomenon that offers a wealth of benefits in mass production through persistent refinement and accumulated knowledge. Immersing you in several industrial examples, Renaud and Paul throw light on how Boeing and the semiconductor industry have leveraged the experience curve to their advantage. Witness firsthand, the complex interplay between efficiency, cost reduction, and the tangible journey of relentless improvement in mass manufacturing setups.

Show Sections

00:00 - Greetings and introduction.

00:51 - The example of Boeing in the 40s and 50s.

04:04 - The theory behind the experience effect.

12:10 - It's more than just individuals improving on the production line...the whole business must evolve.

20:00 - Pilot and starting costs are higher, but don't be tempted to skip ahead.

25:46 - The learning curve.

28:23 - How does the experience effect translate in commercial terms?

32:54 - Who does improvement work the right way?

35:10 - Conclusion.

Related content...

- Robust Design: Enhancing Product Quality and Performance

- 5 steps for a Chinese factory to improve its efficiency

- How To Improve Quality From Your Supplier? [Podcast]

- Keeping your supplier’s costs under control [Podcast]

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday Jan 19, 2024

Friday Jan 19, 2024

Renaud and Andrew Amirnovin, Sofeast's Head of Compliance and Reliability, are talking about the Boeing 737 Max 9 airplane that has been in the news again following a very frightening incident where part of the body blew out leading to a sudden depressurization and emergency landing. But why did this occur? Are there more quality and reliability issues to worry about?

Show Sections

00:00 - Greetings and introduction.

01:18 - What happened on Alaska Airlines Flight 1282 on Jan 5th, 2024?

05:03 - Has the FAA been going too easy on Boeing?

06:33 - Did Boeing rushing to redevelop the 737 lead to catastrophic problems?

10:57 - Why was Boeing under such pressure? A look back over a few decades.

13:43 - Worrying tales from angry former Boeing employees.

18:39 - 737 Max grounding.

22:38 - Time for new leadership at Boeing?

26:52 - FAA audit.

29:32 - Had warnings been properly heeded?

34:12 - Next steps and takeaways.

37:45 - Wrapping up.

Related content...

- Mid-air blowout can 'never happen again,' Boeing CEO says after Alaska Airlines accident

- 'Loose hardware' found on more Alaska Airlines 737 MAX 9 planes

- What happened after the Alaska Airlines flight took off, in 5 charts

- NTSB not sure if the bolts on blown-out door plug on Boeing MAX 9 were even attached (Video)

- Alaska Airlines Blowout Reveals Cockpit Door Vulnerability on Boeing Jet

- You may also like: Why Did The Titan Sub And Siemens Gamesa Wind Turbines Fail?

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday Jan 12, 2024

Cost Vs Quality - How Manufacturers Can Find A Balance

Friday Jan 12, 2024

Friday Jan 12, 2024

Adrian and Renaud tackle the big question of cost versus quality and how they both affect each other in manufacturing. You'll learn common Chinese attitudes towards them, the long-term power of lean, and some achievable levers that can bring you cost and quality benefits that most businesses can implement quickly.

Show Sections

00:00 - Greetings and introduction (inc. our team at CES '24!)

01:50 - What do we mean by Cost V Quality?

04:49 - A typical Chinese manufacturer's logic about quality.

15:29 - The Lean manufacturing ideal.

25:32 - Day-to-day keys that can give you quality and cost benefits.

- 26:38 - Do design for manufacturing and assembly

- 29:30 - Follow a sound NPI process

- 32:57 - Use good tooling and automation

- 35:12 - Staff training for avoiding defects and more

- 37:21 - Experience effects

38:21 - Wrapping up.

Related content...

- Documenting Your Company’s Quality Standard into the Details

- The Design for X Approach: 12 Common Examples

- NPI Process (New Product Introduction)

- What is the “lean” approach to manufacturing, and is it applicable in China?

- Design for manufacturing (Video)

- Design for assembly (Video)

- Get NPI support from Sofeast's engineers to bring your product to market

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB

Friday Jan 05, 2024

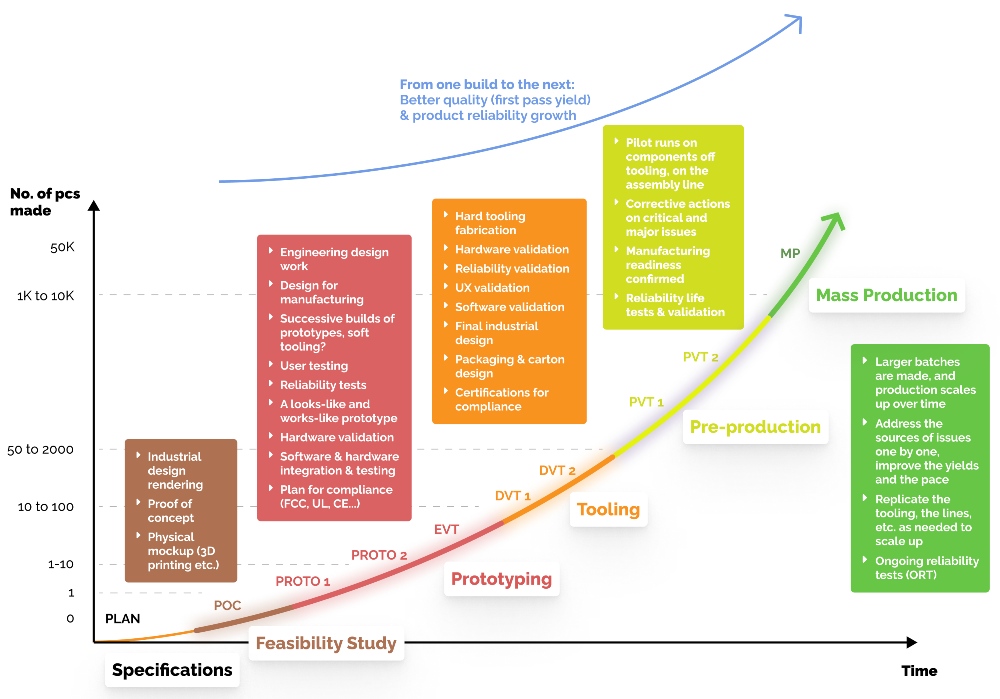

7 Key NPI Tasks To Do Before You Take Your Product Into Production

Friday Jan 05, 2024

Friday Jan 05, 2024

In this episode...

Adrian and Andrew Amirnovin kick off 2024 by going through 7 key New Product Introduction tasks you need to be aware of to get a positive outcome before mass producing your product. If this is the year you bring a product to market, get ahead of the curve by bearing these 7 things in mind from one of our most experienced team members who is also Head of Compliance and Reliability.

Show Sections

00:00 - Greetings and introducing today's topic.

03:01 - 1. Document your requirements early during the design and development phase.

06:36 - 2. Do functionality and reliability testing.

10:19 - 3. Compliance testing and pilot run before pre-production.

13:54 - 4. Do final reliability testing.

15:20 - 5. Lock the BOM.

17:16 - 6. Validate tooling and manufacturing.

20:26 - 7. Focus on shipping in the post-production period.

21:13 - Why it pays importers to be knowledgeable about the NPI phases, even if you work with a manufacturer to do the development and manufacturing.

25:17 - Wrapping up.

Related content...

- What is the NPI process?

- Prototyping Process To Test & Refine a New Product Design

- Avoid Sending Immature Product Designs to a Chinese Manufacturer!

- Transitioning to Manufacturing from Product Development | 2 Options

- The NPI Process: Trouble Awaits If You Skip Its Steps! [Podcast]

Get in touch with us

- Connect with us on LinkedIn

- Send us a tweet @sofeast

- Prefer Facebook? Check us out on FB

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here and don't forget to give us a 5-star rating, please:

Get in touch with us

-

- Connect with us on LinkedIn

- Contact us via Sofeast's contact page

- Subscribe to our YouTube channel

- Prefer Facebook? Check us out on FB